Tool manufacturing with skill and

precision Nisula Oy

Fine mechanics with skill and precision Nisula Oy

For over 40 years, we have designed and manufactured high-quality punching, extrusion and die tools,

combining advanced technology with reliable craftsmanship.

For over 40 years, we have designed and manufactured high-quality cutting, extrusion and die tools, combining advanced technology with reliable craftsmanship.

What We Do

Comprehensive tool solutions from design to delivery on a turnkey basis.

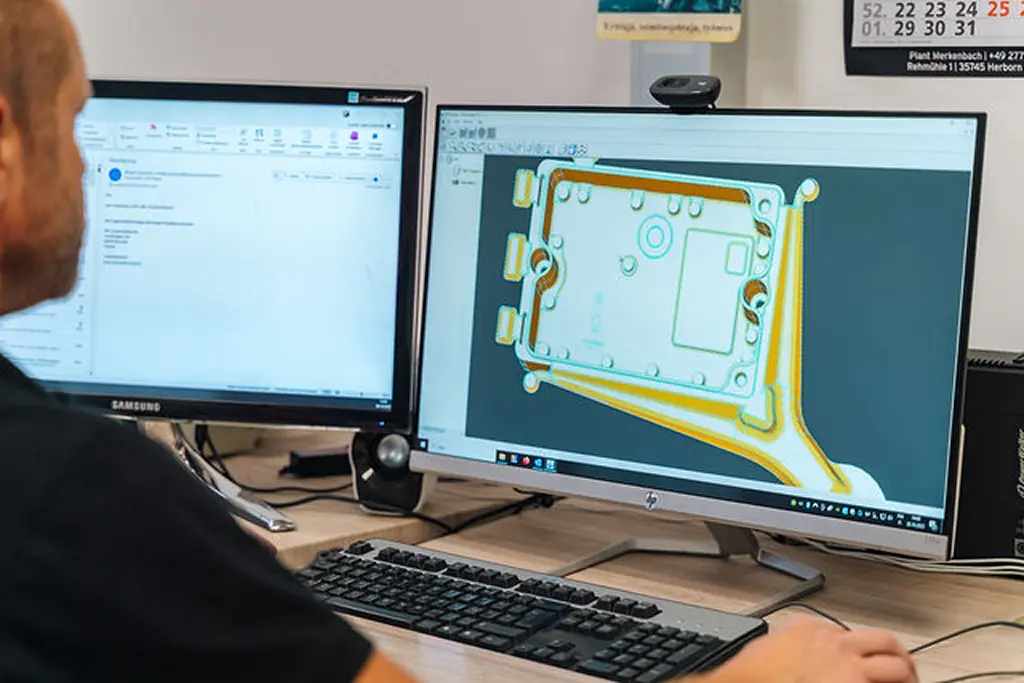

Design

Our core services are tool design, which we do with decades of experience. During this time, we have honed our processes to be efficient and high-quality from both the customer and manufacturing perspective. We are involved in the customer's needs from the beginning and design a functional and cost-effective solution just for you.

Manufacturing

Molds, punching tools, industrial tools manufactured by skilled personnel according to your needs.

Maintenance

Fast and reliable service keeps your production running. Our strength is speed when a customer's tool breaks.

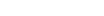

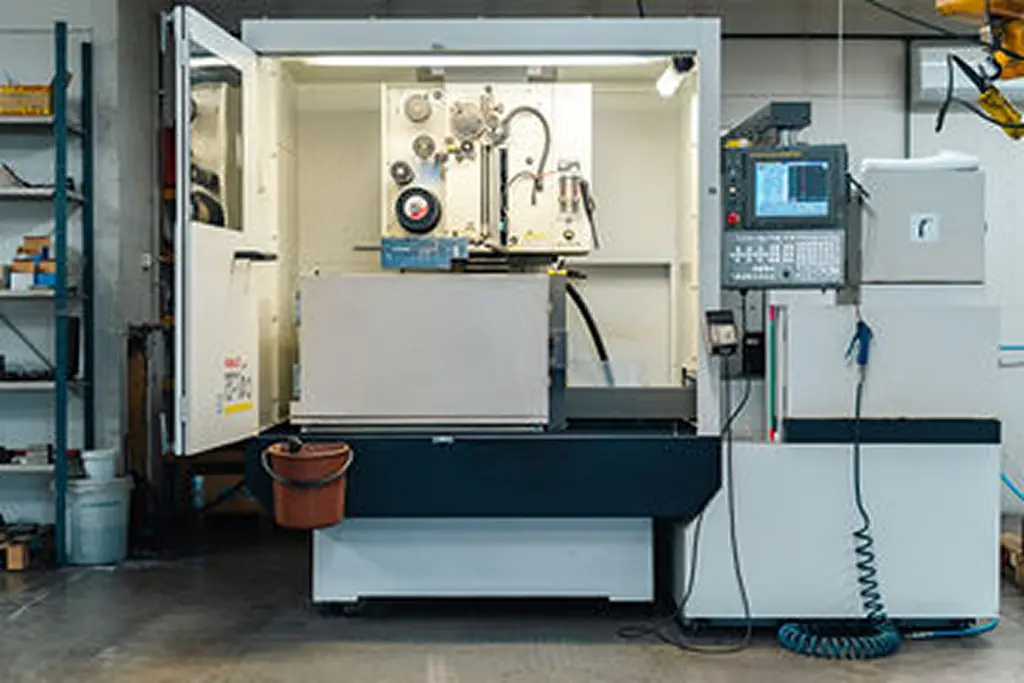

Wire-Cut EDM Machines

One of the few advanced wire EDM cutting technologies in Finland, offering unparalleled precision.

- Fanuc robocut a-C400iB

- Fanuc robocut alfa-0ie

- Fanuc robocut @-0 i A X-320 Y-220 Z-180

- Fanuc robocut a-1ic 550 x 370 x 310 mm

- Drilling EDM machine

Our machine base is built for precision

We continuously invest in the latest technology to ensure that every tool we manufacture meets the required standards.

We continuously invest in the latest technology to ensure that every tool we manufacture meets the required standards.

Wire-Cut EDM Machines

- Fanuc robocut a-C400iB

- Fanuc robocut alfa-0ie

- Fanuc robocut @-0 i A X-320 Y-220 Z-180

- Fanuc robocut a-1ic 550 x 370 x 310 mm

- Drilling EDM machine

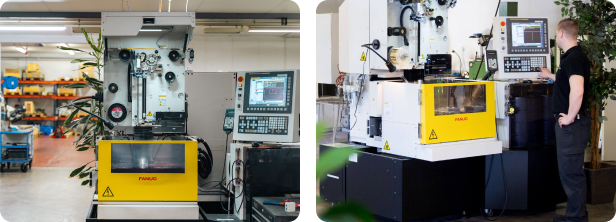

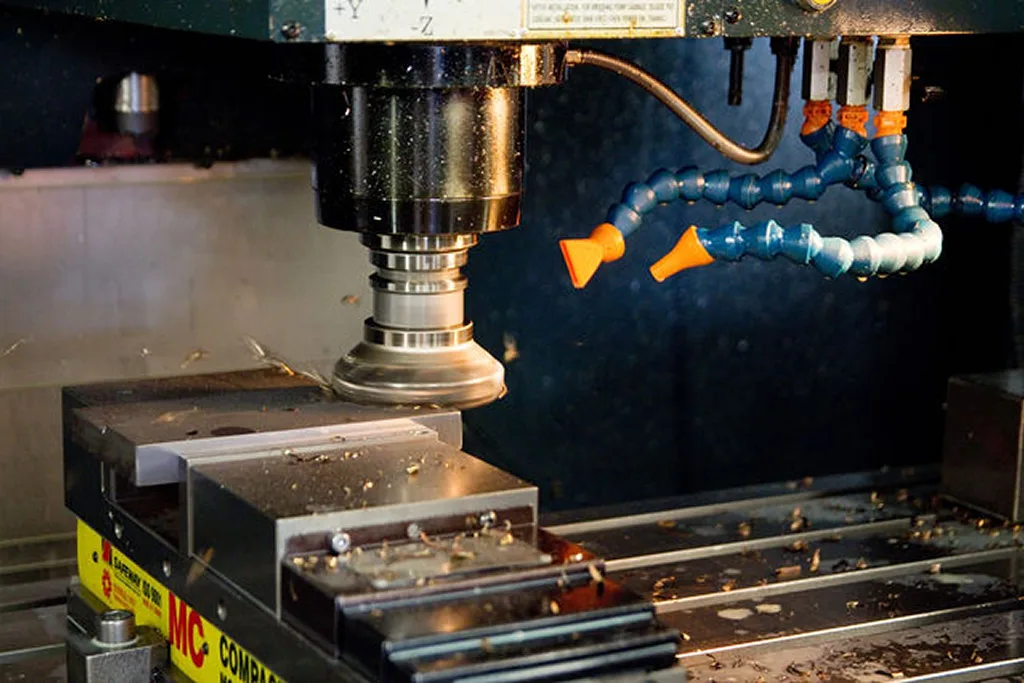

Milling Machine

- Hyundai-Wia F500 Plus

- Chevalier X-1020 Y-510 Z-510

- Johnford SV-41 X1050mm Y610mm Z610mm Renishaw

- OMP-60 and Renishaw TS-27R Measurement System

Other machines

- Orbital sander 610x305mm

- EDM machine Topedm

- Lathe

- Spark machines

- Tempering furnaces

- Welding machines

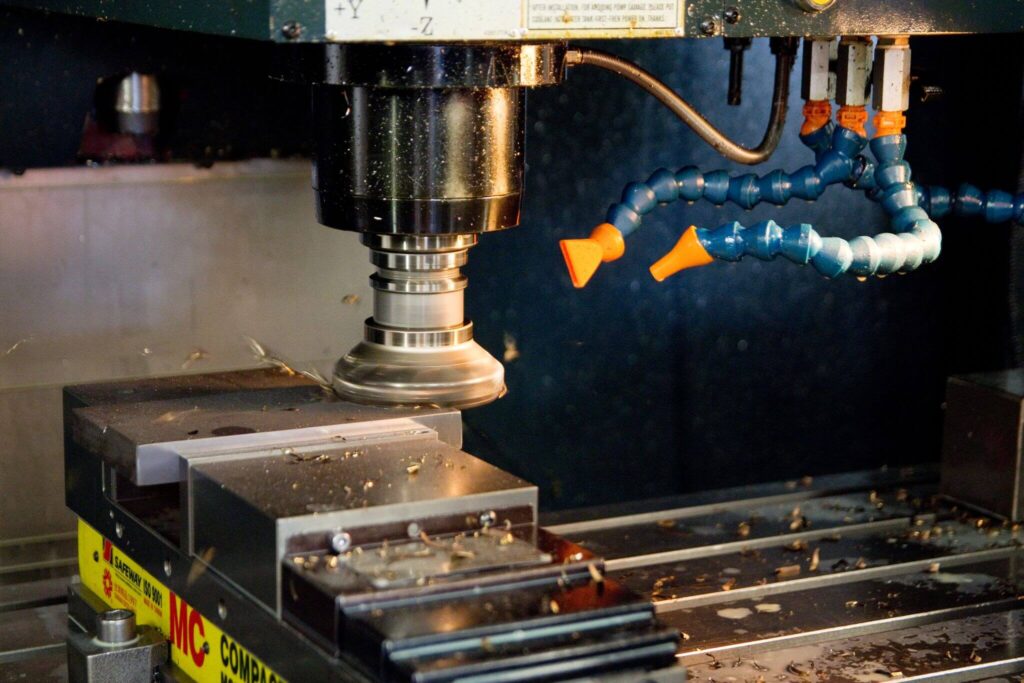

Wire cutting is the precision that defines us when programming top professionals

Wire sawing is a highly precise method for manufacturing precision mechanical parts. The method achieves an accuracy of less than 0.005mm and a surface quality of 0.1Ra-0.6Ra.

Wire sawing is a highly precise method for manufacturing precision mechanical parts. The method achieves an accuracy of less than 0.005mm and a surface quality of 0.1Ra-0.6Ra.

Cutting width

0

mm

Tolerance

0

mm

Diagonal cut

0

°

Precision

0

%

Accuracy

- Tolerances of 0.005 mm

- Complex geometries

- No thermal deformation

High Performance

- Large bevel angle cuts

- Hard materials and carbides

- Wire sawing of sheets in a bundle

Efficiency

- Speed

- Services 24/7

- Engine stock

About Us

Technical excellence and innovations with Finnish precision

What started as a small company has grown into an internationally renowned expert in the engineering industry.

We combine long experience with modern technology to provide efficient and precise solutions to our customers' needs. We use state-of-the-art CNC machining, wire EDM and CAD CAM design to ensure that every project meets the highest quality standards.

What started as a small company has grown into an internationally renowned expert in the engineering industry.

We are proud of the knowledge, attitude and experience of our professionals. We want to help our customers succeed. Our top professionals do their work with top-notch machines. Nisula is known especially for its speed when our customers' needs require it.

YEARS

0

+

1979

FOUNDED

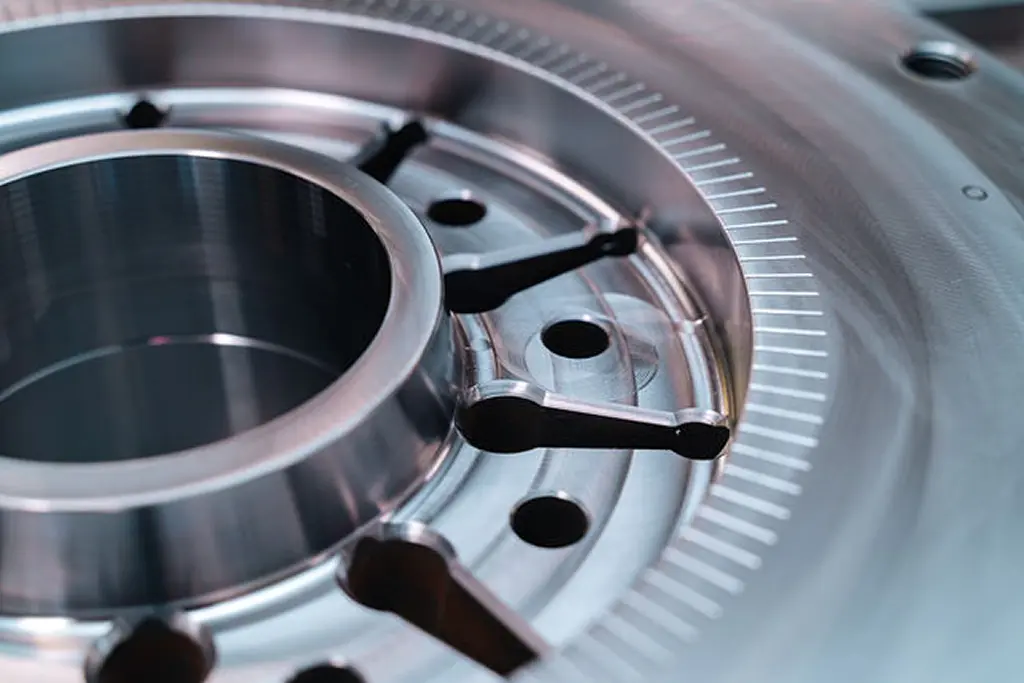

Our work in practice

A peek into our production where precision, technology and craftsmanship combine.

Get in Touch

Let's discuss your next project, we're ready to bring your ideas to life.

Entrepreneur/Sales

Sami Nisula

- +358 50 555 0740

- sami@nisulaoy.fi

Office

Chatrine Enlund-Nisula

- +358 50 381 0284

- chatrine@nisulaoy.fi

Production

Jonas Söderholm

- + 358 50 30 811 97

- jonas@nisulaoy.fi

Founder

Antti Nisula

- +358 50 056 1914